In electronics and engineering, selecting the proper terminals for your project is crucial for ensuring your product’s efficiency, reliability, and longevity. Terminals are the connection points where wires or components are joined, making them a fundamental aspect of any electrical system. The correct terminals can help prevent issues such as poor connections, electrical shorts, and potential fire hazards. This guide will help you understand the key considerations for selecting the best terminals for your needs.

Understanding Wire Terminals

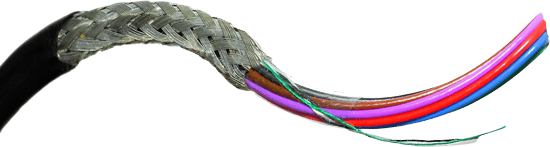

Wire terminals are essential components used to connect wires to a terminal block or to connect one wire to another. These terminals ensure a secure connection and are available in various types, each suited for different applications. Common types include crimp terminals, screw terminals, and push-in terminals, among others.

Key Factors to Consider

- Application Requirements

- Wire Size and Type

- Environmental Conditions

The first step in choosing the right terminal is understanding the specific requirements of your project. Are you working on a residential wiring project or handling industrial machinery? Each application may require different terminal types. For instance, high-vibration environments might benefit from ring terminals offering a more secure connection than spade terminals.

Types of Wire Terminals

- Crimp Terminals

- Screw Terminals

- Push-in Terminals

Crimp terminals are widely used for their ease of installation and reliability. They are available in various forms, including ring, spade, and butt connectors. Crimping involves using a special tool to compress the terminal around the wire, ensuring a secure connection.

Screw terminals are ideal for connections that may need to be adjusted or disconnected frequently. They involve securing the wire by tightening a screw, which clamps the wire in place. This type is commonly used in industrial applications where robust connections are essential.

Best Practices for Installation

- Proper Crimping Techniques

- Adequate Insulation

- Regular Maintenance and Inspection

Choosing the right terminals for your project is not just about selecting the correct size or type; it’s about ensuring your electrical connections’ overall safety and functionality. By considering factors such as the application, wire type, and environmental conditions, you can make an informed decision that will benefit your project in the long run.

If you need further assistance or have specific requirements, don’t hesitate to reach out to our team. We’re here to help you find the perfect solution for your electrical connection needs. Contact us today to discuss your project and how we can support you with the right tools and components.