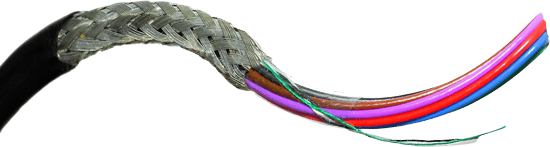

What are Custom Wiring Solutions?

Tailored wiring solutions are crafted with careful consideration to cater to the distinct needs of a specific project or system. This method ensures a precise fit, layout, and operation that generic wiring systems might not offer.

PROS

of Custom Wiring Solutions-

Tailored fit and functionality

-

Improved performance and reliability

-

Increased deign flexibility

-

Compliance with regulations

-

Oprimized space usage

CONS

of Custom Wiring Solutions-

Higher cost

-

Longer lead time

-

Complex installation

PROS in detail

One of the primary advantages of custom wiring solutions is that they are made to fit your exact specifications. Whether your project requires specific wire lengths, connectors, or unique routing through tight spaces, a custom solution can accommodate these needs. This level of customization ensures that your wiring system perfectly integrates with other components, reducing the risk of performance issues and improving overall efficiency.

When wiring is designed with a particular application in mind, it’s more likely to perform optimally. Custom wiring solutions can also account for environmental factors such as temperature, humidity, or chemical exposure, allowing you to choose materials and insulation that will stand the test of time. This leads to greater reliability and less need for future repairs or replacements.

CONS in detail

Custom wiring solutions often come with a higher upfront cost compared to standard solutions. The additional design, development, and manufacturing time can increase the project’s overall price. For projects with tight budgets, this could be a deciding factor.

With custom wiring, installation can sometimes be more complex than with standard solutions. The custom nature of the wiring might require special tools or expertise, which could lead to additional labor costs and time.

What are Standard Wiring Solutions?

Pre-made wiring options are easily accessible for a variety of uses, being produced in large quantities to cater to common wiring requirements.

PROS

of Standard Wiring Solutions-

Cost-effective

-

Short lead time

-

Simplicity and Convenience

-

Reliable for general applications

-

Avalability of components

CONS

of Standard Wiring Solutions-

Limited flexibility

-

Potential for inefficiency

-

Generic designs

PROS in detail

CONS in detail

Making the Right Choice for your Project

Choosing between custom and standard wiring solutions depends on your specific project needs, budget, and timeline. While custom solutions offer tailored performance and design flexibility, they come at a higher cost and longer lead times. On the other hand, standard wiring solutions provide cost-efficiency and convenience but may lack the flexibility required for specialized applications.

If you’re unsure which option is right for you, Riggertronic is here to help. With years of expertise in custom and standard wiring solutions, our team can guide you through the decision-making process to ensure your project is a success. Contact us today to learn more about how we can meet your wiring needs.