What is a wiring harness, and why is it essential for many industries?

For numerous industries, the significance of wire harnesses in cable management cannot be overstated.

These essential components play a crucial role in producing electronic devices, electrical appliances, and medical equipment, effectively meeting diverse cable management needs.

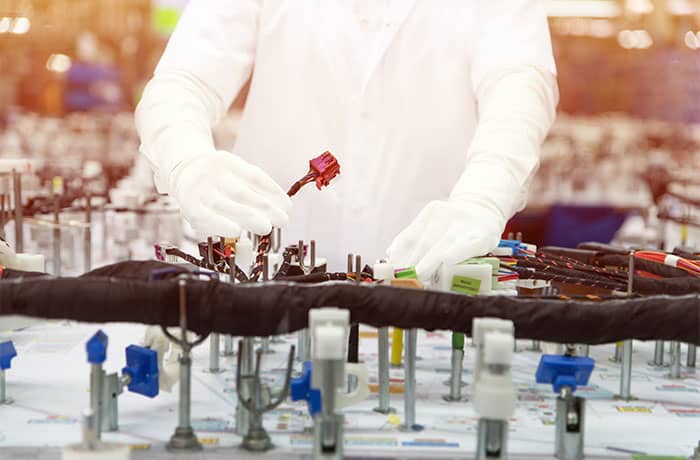

Importance of a wire harness

Given their role in linking and transmitting power between various system components, wiring harnesses play a crucial role in producing robots, aviation machinery, cars, telecommunications devices, and military equipment.

Construction

A harness consists of multiple wires interconnected to link different components within a system. With a multitude of potential functions, a single harness can supply power and transfer data via electrical signals to convey, spread, or interpret information across an entire system. When designing and selecting components, prioritizing quality is crucial. Familiarity with the diverse components aids in the design phase and guarantees adherence to the project's specifications.

The Use of Connectors

Connectors come in various materials, shapes, sizes, and mate types. These materials are specifically chosen to provide protection against various environmental factors, tailored to suit the specific requirements of each project. Connector configurations are varied and can include wire-to-wire, board-to-wire, or board-to-board options. With multiple choices available, connectors may feature 2 to 4 pins or more, weatherproofing capabilities, as well as locking mechanisms.

What are the Terminals for?

At a terminal, two wires come together, linking to a board, each other, or reaching out to another harness. Internal pins in the terminals can control the passage or strength of electrical signals. Various types of terminals are at your disposal, such as spade, hook, quick-connect, bullet, butt, flagged, ring terminals, battery posts, wire ferrules, splices, and lugs.

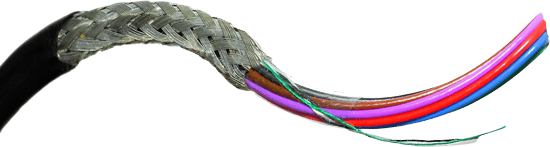

Insulation and Sheath Considerations in Cable Management

The insulation can significantly impact the wire harness's electrical performance and the sheathing it is equipped with. Every project must assess the necessary current load over time to opt for the appropriate insulation and sheathing materials. The insulation demands for a wire harness in automotive applications contrast with those in robotics due to the differing operational environments. Polyvinyl chloride, polyethylene, nylon, thermoplastic rubber, and fluorinated ethylene-propylene are some of the diverse insulation options available.

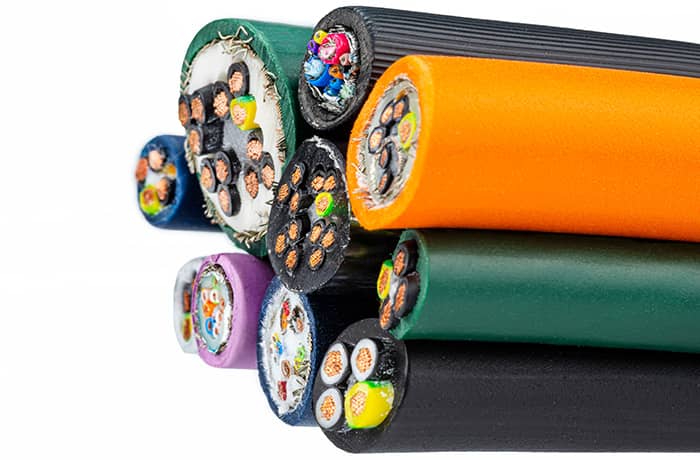

How to choose the right conductor for an electric wire

The quality of wire bundles is closely tied to the metal they contain, so it's crucial to select suitable materials based on the project requirements.

The selection of conductor type is determined by whether the electric wire is intended for power transmission or signal transfer.

Various metals, including copper, steel, aluminum, silver, brass, and bronze, are outstanding conductors widely used in this application.

Using a copper conductor is predominantly preferred for wire manufacturing.

Choosing the right metal for wire bundles is crucial for optimal performance. Copper stands out as the preferred choice due to its superior conductivity. For power transmission applications, copper is highly efficient, ensuring minimal energy loss.

On the other hand, silver and aluminum are also popular choices for specific requirements. By selecting the appropriate metal based on the project's needs, you can enhance the efficiency and reliability of wire bundles, ensuring seamless power transmission or signal transfer.

Riggertronic Specialists are Ready to Assist

A proficient team with expertise in wire assembly and harness structures is crucial for ensuring top-notch ISO quality management and cost-effective solutions for our clients.

Count on our dedicated teams to assist you in crafting a custom harness and define your project’s specifications.

We comprehend the challenges associated with project design, and our advanced factory is equipped with the necessary tools to produce premium end-user wiring harness assemblies.

Allow us to streamline your project with on-time delivery and a dedicated team ready to alleviate the burdens typically associated with project management.